Dynamics 365 is ready to serve efficiently pharmaceutical, chemical companies and food & beverageNormally pharmaceutical and chemical companies dealing with different active ingredients with potency's differs slightly (by nature) than the standard, this will cause a modification in formula contents for each produced batch. Now Dynamics 365 helps production manager to execute daily production efficiently with accurate results.

Target Industries:

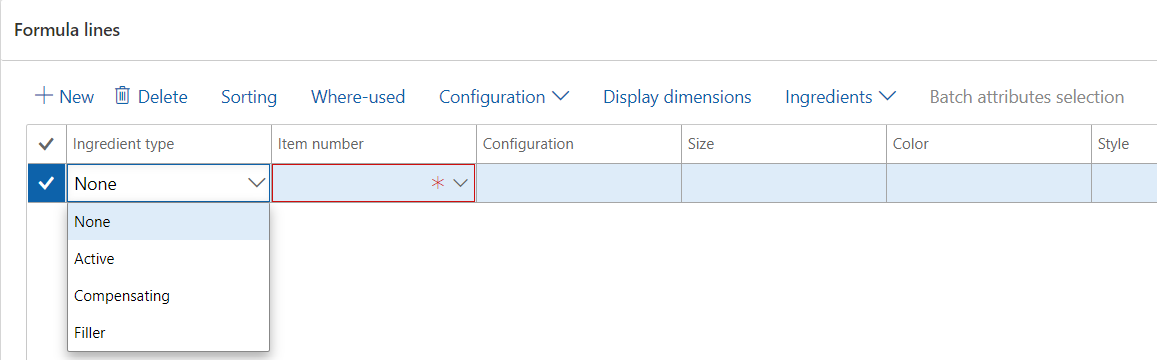

Feature Concept:This feature generates modified production formula based on the potency of the main active ingredient automatically during generating the picking list of each batch order to insure the correct concentration of active ingredients and offsetting materials. Example of this features: In the new Dynamics 365, a field ingredient type is added to describe the characteristics of this material in this formula as following: Active:the main active ingredient in this formula which the system will track its potency. Compensating:Filler:Filler ingredient using the following equation: Filler ingredient Adjustment Quantity = ((Total Estimated Quantities of Active ingredients + Total Estimated Quantities of Compensating ingredients) – (Total Balanced Quantities of Active ingredients + Total Balanced Quantities of Compensating ingredients)) Conclusions:This feature provides:

2 Comments

|

|

|

Saudi Arabia

PO Box 12831 2357, Al Malaz - Zaid Ibn Thabit street, Venicia Building, Riyadh, Saudi Arabia. |

United States4008 Louetta Rd

Spring, Texas 77388 USA |

Home

|

Request a demo

|